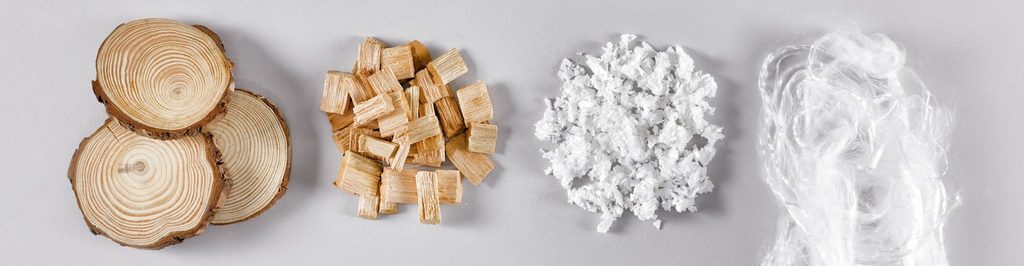

Lenzing Group, a leading global producer of wood-based specialty fibers, announced a strategic collaboration with KARL MAYER GROUP, a world leader in textile machinery, to enable the smooth adoption of a higher percentage of botanic, biodegradable and fossil-fuel-free materials during textile production in both warp knitting and flat knitting machines.

With consumers being more mindful of the environmental impact of the products they purchase, there is a growing trend among leading brands and retailers to offer products that are more sustainable and aesthetical. This partnership will enable the adoption of TENCEL™ Lyocell fibers and TENCEL™ Lyocell filament yarn in warp knitting machines and further reduce the environmental impact of using STOLL flat knitting machines with the use of carbon-zero TENCEL™ fibers in its fully fashioned flat knitting process.

The first three-bar HKS model with electronic guide bar control allows for immediate pattern changes without any mechanical modification and no delay in production.

As a strategic collaboration between Lenzing and KARL MAYER GROUP, the partnership represents an important step by the two companies in guiding the industry towards a more sustainable future and underscores their commitment to empowering partners in the textile chain with value-added solutions and innovation in reducing the carbon footprint of their supply chains.

“As a key player in the industry, Lenzing continues to join hands with like-minded partners to pioneer solutions that improve the quality of textile products and enable the ongoing sustainable development and growth of the industry. Through this partnership with the KARL MAYER GROUP, we will inspire the textile value chain to take proactive steps towards achieving their climate goals with easier adoption of botanic and biodegradable materials, meeting the needs of brands and consumers who are looking for eco-conscious products,” said Florian Heubrandner, Vice President Global Textiles Business at Lenzing.

“The KARL MAYER GROUP is a leading manufacturer of textile machinery and always has its finger on the pulse of its markets. In addition to productivity, sustainability has become a key success factor for our customers. We work with pioneers throughout the textile value chain to provide them with solutions that have a low environmental impact. Yarn is particularly important in this respect. Recycled man-made fibers can be used with high efficiency on our machines. We want to expand the range of materials that can be processed to include petroleum-free yarn variants through our cooperation with Lenzing. In addition to more sustainability, this will also open up the potential for new product developments,” explained Arno Gärtner, CEO of KARL MAYER GROUP.

Increasing Adoption of Fossil-fuel-free Materials in Warp Knitting Machinery

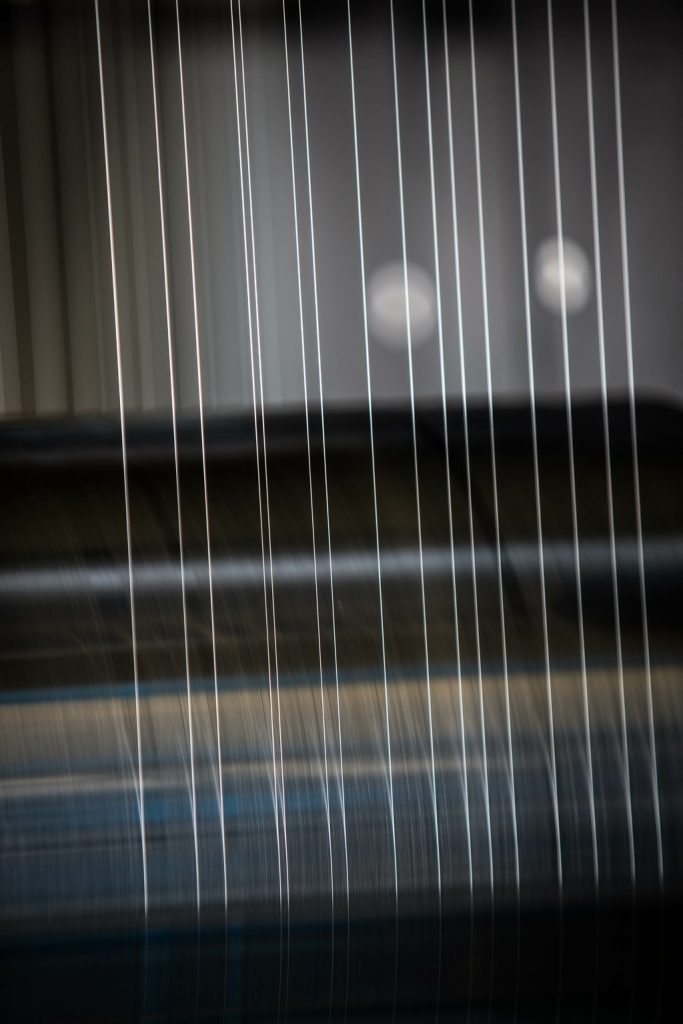

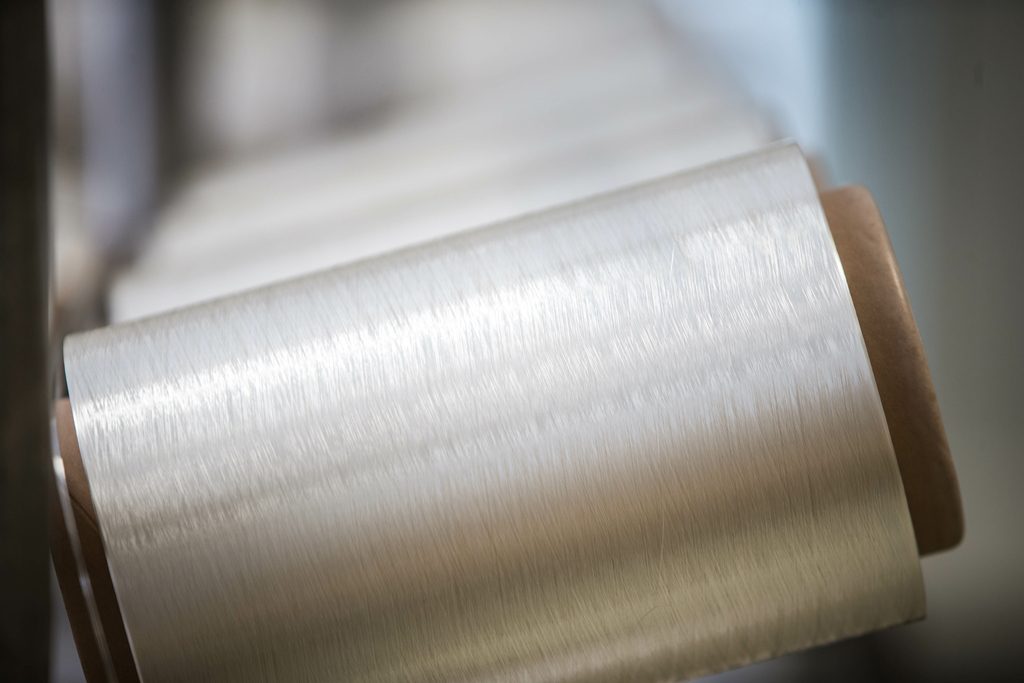

With more value chain partners and brands opting for sustainable raw materials, we need to ensure that existing equipment or machinery that traditionally caters to fibers or yarn made of fossil-based materials can adapt well to botanic alternatives. The partnership between Lenzing and KARL MAYER GROUP strives to enable fossil-fuel-free materials such as TENCEL™ Lyocell fibers and TENCEL™ Lyocell filament yarn to be processed and optimized on KARL MAYER warp knitting machines and demonstrates the possibilities and varieties that can be created in addition with botanic and biodegradable materials.

Leveraging Lenzing’s technical knowledge of the processing of TENCEL™ Lyocell fibers and filament within the value chain, the partnership also supports yarn makers and spinners in their continuous development and adaptation of yarn for new and different textile applications.

Pave the Way for a Sustainable Textile Value Chain with Upgraded Flat Knitting Features

With a shared vision to lower the environmental impact of the production process, the collaboration reduces carbon footprint with carbon-zero TENCEL™ fibers and decreases material consumption on STOLL flat knitting machines.

The ADF 530-32 Ki is the perfect solution for all basic ADF knitting applications.

The knitting method has been applied to an ultrafine flat-knit fabric on gauge 20 machines which qualify to be used for making underwear. The fully fashioned process is new to this field as in underwear cut & sew fabrication is established as best practice. Coupled with adopting renewable energy sources in textile production plants and effective supply chain management, Lenzing and KARL MAYER GROUP marry sustainability with innovation to empower manufacturers to achieve ultra-low carbon emissions using botanic and fossil-fuel-free fibers during the production process.

Lenzing and KARL MAYER GROUP will be showcasing a series of concept products, technical samples, and fabrics at the upcoming ITMA 2023 tradeshow in booths (Hall 2-E212 and Hall 4-B-119) to illustrate the potential of knitting innovation leveraged through the collaboration. From then onwards, textile value chain partners can contact Lenzing and KARL MAYER GROUP to discuss how to achieve greater sustainability in their own operations.

KARL MAYER GROUP

www.karlmayer.com

The KARL MAYER GROUP is a mechanical engineering company that offers its own digital solutions in addition to a wide range of products and services of its sector.

Today, the focus of the Group is on textile machinery building. The business activities are focused on the two most important stitch forming processes, warp knitting and knitting, as well as on the areas of technical textiles, warp preparation for weaving and digitalization.

The brands of the Group are KARL MAYER for warp knitting, warp preparation for weaving and the production of technical textiles, STOLL for flat knitting, KM.ON for digital solutions and STOLL ELECTRONIC for electronic components.

The KARL MAYER GROUP ensures the success of its international customers with economically and technically best products and services, as well as with innovations that move the textile world. KARL MAYER has 3,100 employees. Thanks to its global organization and its claim to produce in its main markets, the group of companies is always close to its customers and their needs. Today, it has subsidiaries in the USA, India, Italy, Hong Kong, Japan, China, Bangladesh and Switzerland, as well as agencies in all parts of the world.

The KARL MAYER GROUP is a German family-owned company, which has focused on financial independence and economic sustainability since its foundation in 1937. As a permanent, reliable partner with decades of experience and a high level of quality in all areas, it supports the competitiveness of its customers and business partners.

TENCEL™

www.tencel.com

TENCEL™ is the flagship brand under The Lenzing Group that covers textile specialty product fiber offerings. Since 1992, the TENCEL™ brand has been driving the evolution of fiber solutions for the apparel and home textile segments through several industry-first innovations and environmentally responsible production processes. Product brands under TENCEL™ include TENCEL™ Active, TENCEL™ Denim, TENCEL™ Home, TENCEL™ Intimate, TENCEL™ Luxe and TENCEL™ for Footwear.

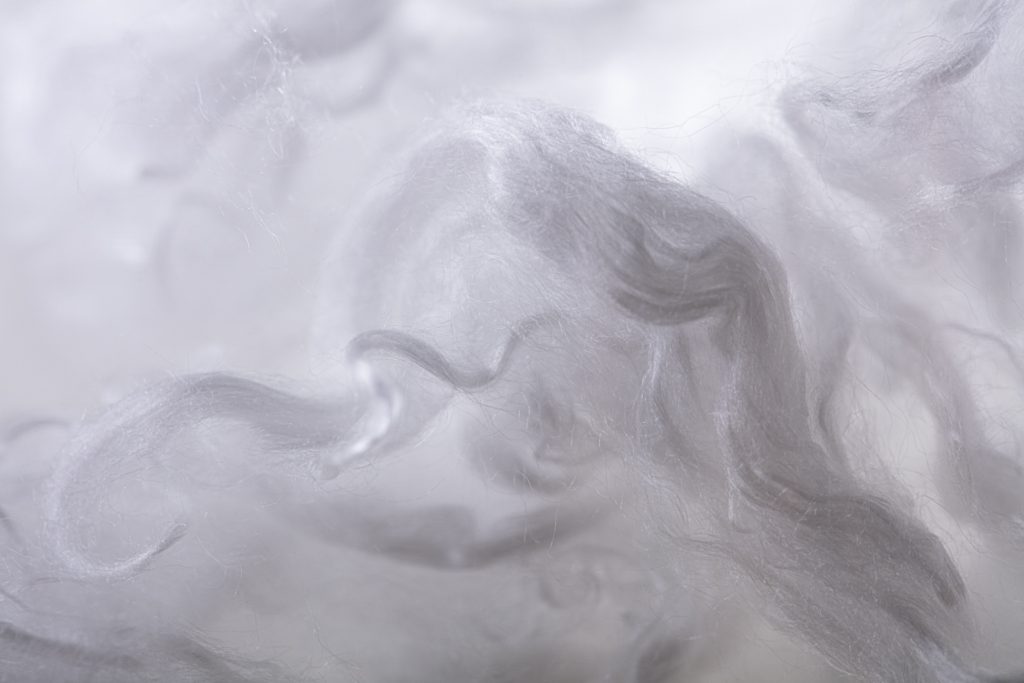

Featuring botanic origin and biodegradable quality, TENCEL™ branded modal and lyocell fibers are also gentle on skin with smooth, long-lasting softness, color vibrancy and color retention features. TENCEL™ Lyocell fibers are versatile and can be combined with a wide range of textile fibers to enhance the aesthetics and functionality of fabrics. Through moisture management, TENCEL™ Lyocell fibers can also absorb moisture efficiently. Offering endless design possibilities, TENCEL™ Modal fibers can be blended with other fibers and processed using conventional machinery, significantly improving the softness and comfort of fabrics.

Fibers and filaments used under the TENCEL™ brand are derived from certified and controlled sources following the stringent guidelines of the Lenzing Wood and Pulp Policy. They are produced via environmentally responsible production processes and are compostable and biodegradable, thus can fully revert back to nature. They are designated by the USDA (U.S. Department of Agriculture) BioPreferred® Program. TENCEL™ Luxe is registered by The Vegan Society.

The Lenzing Group

www.lenzing.com

The Lenzing Group stands for ecologically responsible production of specialty fibers made from the renewable raw material wood. As an innovation leader, Lenzing is a partner of global textile and nonwoven manufacturers and drives many new technological developments.

The Lenzing Group’s high-quality fibers form the basis for a variety of textile applications ranging from elegant ladies clothing to versatile denims and high-performance sports clothing. Due to their consistent high quality, their biodegradability and compostability Lenzing fibers are also highly suitable for hygiene products and agricultural applications.

The business model of the Lenzing Group goes far beyond that of a traditional fiber producer. Together with its customers and partners, Lenzing develops innovative products along the value chain, creating added value for consumers. The Lenzing Group strives for the efficient utilization and processing of all raw materials and offers solutions to help redirect the textile sector towards a closed-loop economy. In order to reduce the speed of global warming and to accomplish the targets of the Paris Climate Agreement and the “Green Deal” of the EU Commission, Lenzing has a clear vision: namely to make a zero-carbon future come true.

All images courtesy of the Lenzing Group & KARL MAYER GROUP.

Tags: apparel, Arno Gärtner, biodegradable, botanic, carbon footprint, carbon-zero, clothing, collaborations, environmental, environmentally-friendly, fashion, fibers, filament, flat knitting, Florian Heubrandner, fossil fuel free, home textiles, Karl Mayer Group, knitting, knitting technique, knitwear, Lenzing, lyocell, machines, materials, natural fibres, petroleum-free yarn, Stoll, supply chains, sustainability, Sustainable, Tencel, TENCEL™ Luxe, textile applications, textile machinery, textiles, Top, warp knitting, warp-knitted, wood, wood based fiber, yarns

Share On Facebook

Share On Facebook Tweet It

Tweet It