Discovering 3D Printing’s Impact on Individuals, Society and the Environment

The Red Dot Design Museum Essen in Germany will present the exhibition “Making a Difference / A Difference in Making” from September 27 to October 30, 2016. The collection brings together pioneering 3D-printed works of art, design, engineering and science. The exhibition is curated by Marta Malé-Alemany, architect and recognized researcher in the field of digital fabrication technologies, and produced by Materialise, a 3D printing company based in Belgium.

Since the origins of 3D printing, artists and designers have embraced the technology and explored its potentials. Their creations often push the boundaries of what is hypothetically possible, and 3D printing companies and experts take up these experimental challenges to advance their own research. This synergy enables and inspires the expansion of 3D printing to other domains: often it results in technical discoveries that are transferred to successful industrial applications.

Since the origins of 3D printing, artists and designers have embraced the technology and explored its potentials. Their creations often push the boundaries of what is hypothetically possible, and 3D printing companies and experts take up these experimental challenges to advance their own research. This synergy enables and inspires the expansion of 3D printing to other domains: often it results in technical discoveries that are transferred to successful industrial applications.

The exhibition “Making a Difference / A Difference in Making” looks at 3D printing with both the eyes of innocent fascination and deeper observation. It aims to ponder how it can help individuals, enable social changes and positively contribute to the environment. In other words, how 3D printing is making a difference.

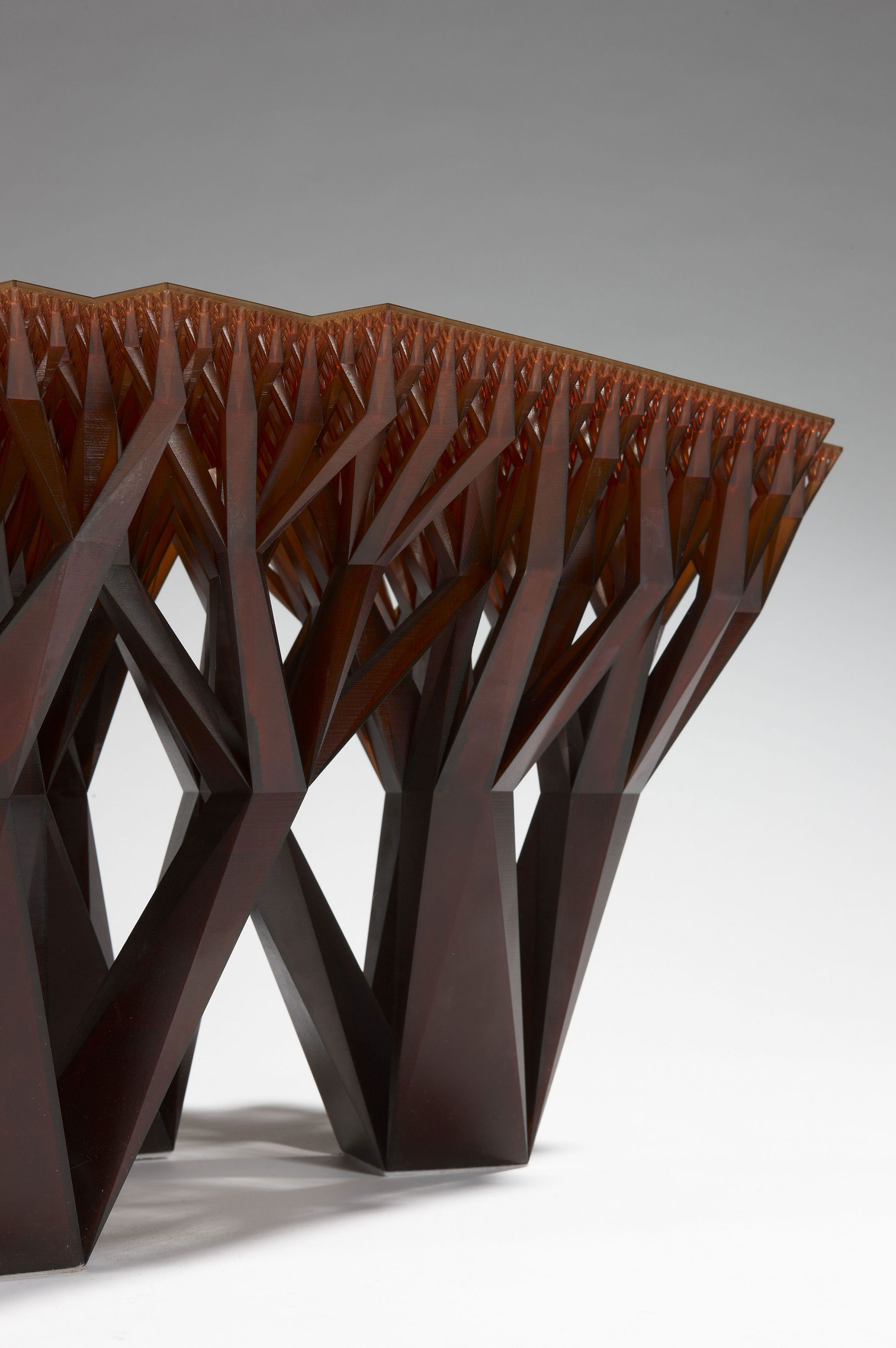

In Germany for the first time, this exhibition offers a unique opportunity to explore pluralistic aspects and applications of this disruptive technology. Visitors will be able to see the work of renowned artists and designers such as Patrick Jouin, Iris van Herpen, Jan Wertel, Gernot Oberfell and Daniel Widrig among others. A previous edition took place in 2015 at The Centre for Fine Arts in Brussels and was highly acclaimed by both specialists and the general audience.

In Germany for the first time, this exhibition offers a unique opportunity to explore pluralistic aspects and applications of this disruptive technology. Visitors will be able to see the work of renowned artists and designers such as Patrick Jouin, Iris van Herpen, Jan Wertel, Gernot Oberfell and Daniel Widrig among others. A previous edition took place in 2015 at The Centre for Fine Arts in Brussels and was highly acclaimed by both specialists and the general audience.

Escapism Show, Iris van Herpen in collaboration with Daniel Widrig and Materialise. Photo © Michel Zoeter.

FRACTAL Table – Jan Wertel Gernot Oberfell with Matthias Bär. Photo by Stéphane Briolant Paris.

#CAST (pronounced “Hash Cast”) is the new way to customize your broken arm cast with personal messages aggregated from your family and friends through social media. A 3D Printer cast comes from using the latest in advanced manufacturing technologies and 3D CAD software, an arm can be 3D scanned at a doctor’s office and a one-of-a-kind cast made in a breathable nylon material using an additive technology called Selective Laser Sintering (SLS). Using the #CAST mobile app, users can approve or reject personalized messages collected through their preferred social networks. Once the maximum amount of characters allowed are approved by the user, a custom fit design is generated and built then delivered to their medical facility and fitted on the user by a specialist. Photo courtesy of studiofathom.com

The Mobelife aMace® implant by Materialise. Photo by Materialise.

Materialise and Toyota worked together to create 3D Printed lightweight car seat. Photo by Materialise.

The Gate – Tomas Libertiny sets a relationship between nature and technology by 3D printing a miniature gate structure. Photo by Materialise.

For more information:

Red Dot Design Museum Essen

www.red-dot-design-museum.de

Materialise

www.materialise.com

Tags: 3D Printed, 3D Printing, architectural, architecture, Daniel Widrig, Essen, Germany, Gernot Oberfell, Iris van Herpen, Jan Wertel, jewelry, Materialise, Patrick Jouin, Red Dot Design Museum, structure, textures

Share On Facebook

Share On Facebook Tweet It

Tweet It